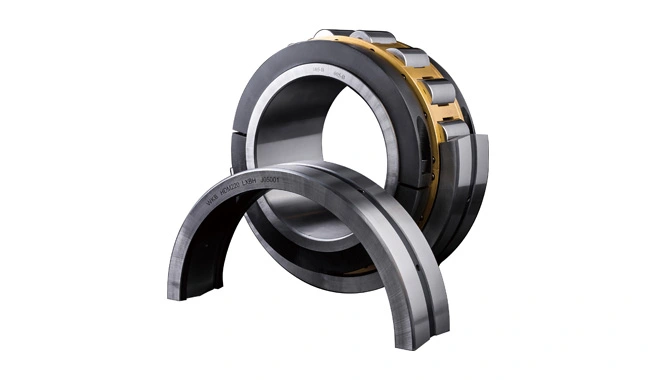

Split Spherical Roller Bearings (Inch) feature a split housing and double row of spherical rollers. These bearings are designed for easy installation and replacement in tight spaces, reducing downtime. They excel in managing heavy loads and misalignment, catering to industrial needs that demand both flexibility and dependability.

Split Design

- The most distinctive feature is the split construction, which allows the bearing to be easily installed or removed without the need to disassemble adjacent components. This split design is particularly advantageous in applications where accessibility is limited.

Reduction in Downtime

- The split configuration significantly reduces downtime during maintenance and replacement procedures. This is crucial for applications that require minimal interruption to operations.

Double Row Design

- Split spherical roller bearings typically have a double row of rollers, providing increased load-carrying capacity and improved performance under heavy radial and axial loads.

Interchangeability

- Split spherical roller bearings are designed to be interchangeable with non-split bearings. This interchangeability provides flexibility in adapting to existing systems or upgrading equipment.

Spherical Roller Design

- The spherical roller design allows the bearing to accommodate misalignment and axial displacement, making it suitable for applications with shaft deflection or mounting errors.

These features collectively make split spherical roller bearings (inch) suitable for applications where ease of maintenance, interchageability, and reliable performance under heavy loads are critical considerations.

Split spherical roller bearings (inch) find applications in various industries and machinery where their unique design and features are advantageous. Some common applications include:

Steel Industry

- In steel manufacturing plants, split spherical roller bearings are used in equipment such as rolling mills and continuous casting machines. The split design facilitates easier maintenance and replacement in these heavy-duty applications.

Mining and Quarrying

- The robust construction and ability to handle heavy loads make split spherical roller bearings suitable for use in mining equipment, crushers, and conveyors where reliable performance under challenging conditions is essential.

Paper and Pulp Industry

- In paper and pulp processing machinery, split spherical roller bearings are employed in various components such as rollers and dryer sections. The split design allows for efficient replacement during maintenance shutdowns.

Industrial Gearboxes

- Gearboxes in various industrial applications, such as those used in conveyors, mixers, and processing equipment, may utilize split spherical roller bearings for their load-carrying capacity and ease of replacement.

Pulp and Paper Mills

- Split spherical roller bearings are commonly found in pulp and paper mill equipment, including pulp digesters, washers, and drying machines. The split design is advantageous during routine maintenance and inspections.

The applications mentioned above highlight the versatility of split spherical roller bearings (inch) across a range of industries, particularly in heavy-duty machinery and equipment where reliability and ease of maintenance are crucial considerations.

| Basic Size | Basic load rating dynamic, static | Calculation cefficient | Fatigue load limtited value | Designation | ermitted axial load' max | Limit Speed | Screw tightening torque | Replace non-split spherical roller bearing | Suitable bearing | Mass | |||||||||||||

| with withdrawal sleeves | housing**) | ||||||||||||||||||||||

| d | d | D | C | B | rmin | C | C。 | e | Y1 | Y2 | Y0 | Fa | Mi | Ma | Bearing | Withdrawal sleeves | Withdrawal sleeves | ||||||

| mm | inch | kN | - | Cur | - | kN | min-1 | Nm | Nm | kg | |||||||||||||

| 100.013 | 3.9375 | 200 | 53 | 92 | 2.1 | 360 | 465 | 0.24 | 2.84 | 4.23 | 2.78 | 39.5 | 222S.315 | 13.8 | 1 500 | 35 | 14 | 22222K | SNW22.315 | H322.315 | SAF522 | SNV200 | 8.88 |

| 101.6 | 4 | 200 | 53 | 92 | 2.1 | 360 | 465 | 0.24 | 2.84 | 4.23 | 2.78 | 39.5 | 222S.400 | 13.8 | 1 500 | 35 | 14 | 22222K | SNW22.400 | H322.400 | SAF522/4 | SNV200 | 8.83 |

| 106.363 | 4.1875 | 215 | 58 | 98 | 2.1 | 455 | 585 | 0.25 | 2.71 | 4.04 | 2.65 | 47 | 222S.403 | 13.8 | 1300 | 35 | 14 | 22224K | SNW24.403 | H3124.403 | SAF524 | SNV215 | 11 |

| 112.713 | 4.4375 | 230 | 64 | 104 | 3 | 540 | 720 | 0.25 | 2.71 | 4.04 | 2.65 | 53 | 222S.407 | 13.8 | 1200 | 35 | 14 | 22226K | SNW26.407 | H3126.407 | SAF526 | SNV230 | 14.7 |

| 114.3 | 4.5 | 230 | 64 | 104 | 3 | 540 | 720 | 0.25 | 2.71 | 4.04 | 2.65 | 53 | 222S.408 | 13.8. | 1200 | 35 | 14 | 22226K | SNW26.408 | H3126.408 | SAF526/4.1/2 | SNV230 | 14.4. |

| 125.413 | 4.9375 | 250 | 68 | 110 | 3 | 630 | 880 | 0.26 | 2.62 | 3.9 | 2. 56 | 60 | 222S.415 | 13.8 | 1100 | 35 | 14 | 22228K | SNW28.415 | H3128.415 | SAF528 | SNV250 | 17.8 |

| 125.413 | 4.9375 | 250 | 68 | 110 | 3 | 585 | 780 | 0.26 | 2.62 | 3.9 | 2. 56 | 53 | 222S.415-MA | 13.8 | 850 | 35 | 14 | 22228K | SNW28.415 | H3128.415 | SAF528 | SNV250 | 17.9 |

| 127 | 5 | 250 | 68 | 110 | 3 | 630 | 880 | 0.26 | 2.62 | 3.9 | 2. 56 | 60 | 222S.500 | 13.8 | 1100 | 35 | 14 | 22228K | SNW28.500 | H3128.500 | SAF528/5 | SNV250 | 17.5 |

| 131.763 | 5.1875. | 270 | 73 | 122 | 3 | 735 | 1020 | 0.25 | 2.67 | 3.97 | 2.61 | 73 | 222S.503 | 22.2 | 1000 | 69 | 35 | 22230K | SNW30.503 | H3130.503 | SAF530 | SNV270 | 25.2 |

| 138.113 | 5.4375 | 290 | 80 | 124 | 3 | 850 | 1200 | 0.25 | 2.69 | 4 | 2.63 | 83 | 222S.507 | 22.2 | 950 | 69 | 35 | 22232K | SNW32.507 | H3132.507 | SAF532 | SNV290 | 28.9 |

| 138.113 | 5.4375 | 290 | 80 | 124 | 3 | 780 | 1060 | 0.25 | 2.69 | 4 | 2.63 | 74 | 222S.507-MA | 22.2 | 750 | 69 | 35 | 22232K | SNW32.507 | H3132.507 | SAF532 | SNV290 | 31.3 |

| 139.7 | 5.5 | 240 | 60 | 106 | 2.1 | 450 | 680 | 0.22 | 3.1 | 4.62 | 3.03 | 51 | 230S.508-MA | 13.8 | 900 | 35 | 8.5 | 23032K | SNP3032. 508 | H3032.508 | SAF032K/5.1/2 | 13.7 | |

| 139.7 | 5. 5000 | 290 | 80 | 124 | 3 | 850 | 1200 | 0.25 | 2.69 | 4 | 2.63 | 83 | 222S.508 | 22.2 | 950 | 69 | 35 | 22232K | SNW32.508 | H3132.508 | SAF532/5.1/2 | SNV290 | 28.6 |

| 150.813 | 5.9375 | 310 | 86 | 128 | 4 | 965 | 1370 | 0.26 | 2.64 | 3.93 | 2.58 | 94 | 222S.515 | 22.2 | 900 | 69 | 35 | 22234K | SNW34.515 | H3134.515 | SAF534 | 35.5 | |

| 152.4 | 6.0000 . | 310 | 86 | 128 | 4 | 965 | 1370 | 0.26 | 2.64. | 3.93 | 2.58 | 94 | 222S.600 | 22.2 | 900 | 69 | 35 | 22234K | SNW34. 600 | H3134.600 | SAF534/6 | 36.5 | |

| 163.513 | 6.4375 | 280 | 74 | 123 | 2.1 | 640 | 1000 | 0.23 | 2.98 | 4.44 | 2.92 | 96 | 230S.607-MA | 22.2 | 750 | 69 | 14 | 23038K | SNP3036.607 | H3038.607 | SAF038K/6.7/16 | 24.4 | |

| 6.4375 | 300 | 96 | 140 | 2.1 | 830 | 1220 | 0.29 | 2.32 | 3.45 | 2.26 | 100 | 231S.607-MA | 22.2 | 670 | 69 | 35 | 23136K | SNP3136.607 | H3136.607 | SDAF3136K/6.7/16 | 34.4. | ||

| 6.4375 | 320 | 86 | 131 | 4 | 965 | 1370 | 0.26 | 2.64 | 3.93 | 2. 58 | 94 | 222S.607 | 22.2 | 900 | 69 | 35 | 22236K | SNW36.607 | H3136.607 | SAF536 | 37.5 | ||

| 165.1 | 6.5 | 320 | 86 | 131 | 4 | 965 | 1370 | 0.26 | 2.64 | 3.93 | 2.58 | 94 | 222S.608 | 22.2 | 900 | 69 | 35 | 22236K | SNW36.608 | H3136.608 | SAF536/6.1/2 | 37.8 | |

| 176.213 | 6.9375 | 340 | 92 | 142 | 4 | 1140 | 1630 | 0.25 | 2.71 | 4.04 | 2.65 | 111 | 222S.615 | 22.2 | 800 | 69 | 35 | 22238K | SNW38.615 | H3138.615 | SAF538 | 44.2 | |

| 177.8 | 7 | 290 | 75 | 120 | 2.1 | 780 | 1250 | 0.23 | 2.9 | 4.31 | 2.83 | 113 | 230S.700 | 22.2 | 700 | 69 | 14 | 23038K | SNP3038.700 | H3038.700 | SAF038K/7 | 21.1 | |

| 182.563 | 7. 1875 | 360 | 98 | 154 | 4 | 1140 | 1630 | 0.25 | 2.71 | 4.04 | 2.65 | 104 | 222S.703 | 22.2 | 600 | 69 | 35 | 22240K | SNW40.703 | H3140.703 | SAF540 | 59 | |

| 190.5 | 7. 5000 | 400 | 108 | 162 | 4 | 1340 | 1900 | 0.25 | 2.69 | 4 | 2.63 | 121 | 222S.708 | 32 | 560 | 120 | 69 | 22244K | SNW44.708 | H3144X.708 | SAF544/7.1/2 | 73.3 | |

| 201.613 | 7.9375 | 400 | 108 | 162 | 4 | 1340 | 1900 | 0.25 | 2.69 | 4 | 2.63 | 121 | 222S.715 | 32 | 560 | 120 | 69 | 22244K | SNW44.715 | H3144X.715 | SAF544 | 75.4 | |

| 203.2 | 8 | 400 | 108 | 162 | 4 | 1340 | 1900 | 0.25 | 2.69 | 4 | 2.63 | 121 | 222S.800 | 32 | 560 | 120 | 69 | 22244K | SNW44.800 | H3144X.800 | SAF544/8 | 74.7 | |

| 214.313 | 8.4375 | 360 | 92 | 156 | 3 | 1100 | 1830 | 0.23 | 2.9 | 4.31 | 2.83 | 152 | 230S.807 | 32 | 560 | 120 | 35 | 23048K | SNP3048.807 | H3048.807 | SAF048K/8.7/16 | 54.7 | |

| 215.9 | 8.5 | 360 | 92 | 156 | 3 | 1100 | 1830 | 0.23 | 2.9 | 4.31 | 2.83 | 152 | 230S.808 | 32 | 560 | 120 | 35 | 23048K | SNP3048.808 | H3048.808 | SAF048K/8.1/2 . | 58.9 | |

| 228.6 | 9 | 360 | 92 | 156 | 3 | 1100 | 1830 | 0.23 | 2.9 | 4.31 | 2.83 | 152 | 230S.900 | 32 | 560 | 120 | 35 | 23048K | SNP3048.900 | H3048.900 | SAF048K/9 | 52.8 | |

| 239.713 | 9.4375 | 440 | 144 | 210 | 4 | 1860 | 3050 | 0.3 | 2.28 | 3.39 | 2.23 | 218 | 231S.907 | 32 | 450 | 120 | 69 | 23152K | SNP3152.907 | H31 52X.907 | SDAF3152K/9.7/16 | 113 | |

| 241.3 | 9. 5000 | 400 | 104 | 160 | 4 | 1220 | 2120 | 0.22 | 3.04 | 4.53 | 2.97 | 177 | 230S.908 | 32 | 560 | 120 | 69 | 23052K | SNP3052.908 | H3052X.908 | SAF052K/9.1/2 | 56.8 | |

| 260 | 9.9375 | 460 | 146 | 190 | 5 | 2280 | 3800 | 0.3 | 2.23 | 3.32 | 2.18 | 255 | 231S.915 | 32 | 400 | 120 | 35 | 231 56K | SNP3156.915 | H3156X.915 | SDAF3156K/9.15/16 | 116 | |

| 254 | 10 | 420 | 106 | 170 | 4 | 1460 | 2450 | 0.23 | 2.95 | 4.4 | 2.89 | 200 | 230S.1000 | 32 | 500 | 120 | 35 | 23056K | SNP3056. 1000 | H3056.1000 | SAF056K/10 | 71.2 | |

| 266.7 | 10.5 | 420 | 106 | 170 | 4 | 1 460 | 2450 | 0.23 | 2.95 | 4.4 | 2.89 | 200 | 230S.1008 | 32 | 500 | 120 | 35 | 23056K | SNP3056. 1008 | H3056.1008 | SAF056K/10.1/2 | 59.7 | |

| 279.4 | 11 | 460 | 118 | 176 | 4 | 1 600 | 2800 | 0.22 | 3.04 | 4.53. | 2.97 | 228 | 230S.1100 | 32 | 480 | 120 | 69 | 23060K | SNP3060. 1100 | H3060.1100 | SDAF060K/11 | 91.7 | |

| 11 | 500 | 160 | 218 | 5 | 2320 | 3900 | 0.29 | 2.32 | 3.45 | 2.26 | 265 | 231S.1100 | 44 | 400 | 190 | 120 | 23160K | SNP3160.1100 | H3160HG.1100 | SDAF3160K/11 | 160 | ||

| 304.8 | 12 | 480 | 121 | 186 | 4 | 1860 | 3200 | 0.23 | 2.9 | 4.31 | 2.83 | 255 | 230S.1200 | 32 | 430 | 120 | 69 | 23064K | SNP3064. 1200 | H3064HG.1200 | SDAFO64K/ 12 | 96.5 | |

| 12 | 540 | 176 | 225 | 5 | 2750 | 4750 | 0.29 | 2.3 | 3.42 | 2.25 | 305 | 231S.1200 | 60 | 360 | 295 | 120 | 231 64K | SNP3164. 1200 | H3164HG.1200 | SDAF3164K/12 | 1 84 | ||

| 330.2 | 13 | 540 | 134 | 205 | 5 | 2360 | 4150 | 0.22 | 3.01 | 4.48 | 2.94 | 315 | 230S.1300 | 60 | 380 | 295 | 69 | 23072K | SNP3072. 1300 | H3072HG.1300 | SDAF072K/13 | 165 | |

| 13 | 600 | 192 | 270 | 5 | 3900 | 6800 | 0.3 | 2.25 | 3.34 | 2.2 | 410 | 231S.1300 | 60 | 300 | 295 | 35 | 23172K | SNP3172. 1300 | H31 72HG.1300 | SDAF3172K/13 | 288 | ||

| 355.6 | 14 | 560 | 135 | 218 | 5 | 2550 | 4650 | 0.22 | 3.1 | 4.62 | 3.03 | 350 | 230S.1400 | 60 | 380 | 295 | 69 | 23076K | SNP3076.1400 | H3076HG.1400 | SDAF076K/14 | 158 | |

| 14 | 620 | 194 | 270 | 5 | 3900 | 6950 | 0.21 | 2.28 | 3.39 | 2.23 | 420 | 231S.1400 | 60 | 300 | 295 | 69 | 23176K | SNP3176.1400 | H3176HG.1400 | SDAF3176K/14 | 273 | ||

| 381 | 15 | 600 | 148 | 225 | 5 | 2700 | 5100 | 0.28 | 3.2 | 4.77 | 3.13 | 390 | 230S.1500 | 60 | 380 | 295 | 120 | 23080K | SNP3080. 1500 | H3080HG.1500 | SDAFO80K/15 | 192 | |

| 15 | 650 | 200 | 270 | 6 | 4050 | 7200 | 0.3 | 2.39 | 3.56 | 2.34 | 440 | 231S.1500 | 60 | 300 | 295 | 120 | 23180K | SNP3180.1500 | H3180HG.1500 | SDAF3180K/15 | 296 | ||

| 406.4 | 16 | 650 | 157 | 225 | 5 | 3100 | 5850 | 0.21 | 3.2 | 4.77 | 3.13 | 425 | 230S.1600 | 60 | 340 | 295 | 120 | 23088K | SNP3088. 1600 | H3088HG.1600 | SDAF088K/16 | 225 | |

| 16 | 720 | 226 | 315 | 6 | 5400 | 9650 | 0.29 | 2.3 | 3.42 | 2.25 | 570 | 231S.1600 1) | 96 | 260 | 580 | 120 | 23188K | SNP3188. 1600 | H31 88HG.1600 | SDAF3188K/16 | 547 | ||