At WKB-Bearing, we’ve seen how tapered roller bearings power everything from car wheels to heavy industrial machines. These robust components are designed to handle both radial and axial loads, making them a favorite in demanding applications. But what exactly are tapered roller bearings, how do they work, and why are they so widely used? Let me walk you through their design, types, applications, and key differences from other bearings, sharing insights we’ve gained to help you understand why our China tapered roller bearings are a top choice for industries worldwide.

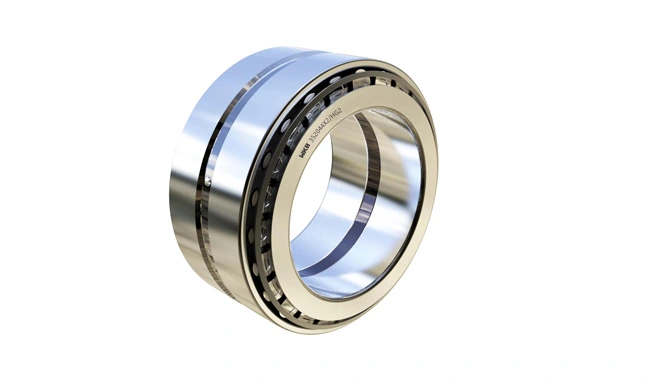

Tapered roller bearings are rolling-element bearings with conical rollers that sit between an inner ring (cone) and an outer ring (cup). Unlike cylindrical roller bearings, which focus on radial loads, these bearings excel at handling both radial (perpendicular to the shaft) and axial (thrust) loads due to their tapered design. The conical rollers make line contact with the raceways, distributing forces evenly and reducing friction.

Why They’re Special: We love how their ability to manage combined loads makes them ideal for applications like vehicle axles or industrial gearboxes. At WKB-Bearing, we produce high-quality China tapered roller bearings that meet global standards for durability and performance.

.jpg)

Picture a tapered roller bearing as a team of conical rollers working together to keep a shaft spinning smoothly under heavy, complex loads. The rollers are guided by a cage to avoid touching each other, which cuts down on friction. The inner ring (cone) fits onto the shaft, while the outer ring (cup) sits in the housing. As the shaft rotates, the tapered rollers roll along the angled raceways, handling both radial and axial forces at once.

Key Mechanics:

· Line Contact: The conical rollers create a line of contact with the raceways, spreading loads over a larger area for better capacity.

· Axial Load Handling: The taper angle allows the bearing to support thrust loads, with steeper angles increasing axial capacity.

· Separable Design: The cone and cup can be separated, making installation and maintenance straightforward.

Insight: We’ve learned that the taper angle is a game-changer. A steeper angle boosts axial load capacity but may reduce radial capacity, so we carefully match the bearing to the application’s load profile.

We deal with several types of tapered roller bearings, each tailored for specific needs:

· Single-Row Tapered Roller Bearings: The most common type, handling combined radial and axial loads in one direction. We use these in automotive wheels and gearboxes.

· Double-Row Tapered Roller Bearings: Two rows of rollers for higher load capacity, perfect for heavy machinery like construction equipment.

· Four-Row Tapered Roller Bearings: Built for extreme loads, these are our choice for steel mill roll-necks or mining equipment.

· Thrust Tapered Roller Bearings: Designed for heavy axial loads, used in applications like screw-down mechanisms in rolling mills.

· Matched Pair Bearings: Pre-assembled pairs (back-to-back or face-to-face) for precision and higher load capacity, common in machine tools.

Table: Types of Tapered Roller Bearings

Type | Features | Common Applications |

Single-Row | Combined radial/axial loads, one direction | Automotive wheels, gearboxes |

Double-Row | Higher load capacity, two directions | Construction equipment, cranes |

Four-Row | Extreme load capacity | Steel mills, mining |

Thrust Tapered | High axial load capacity | Rolling mill screw-downs |

Matched Pair | Precision, high load | Machine tools, heavy machinery |

We’ve seen tapered roller bearings excel in a variety of industries due to their versatility:

· Automotive: Wheel hubs, transmissions, and differentials rely on them for handling combined loads.

· Industrial Machinery: Gearboxes, pumps, and compressors use them for durability under heavy loads.

· Construction: Excavators and bulldozers depend on their ability to withstand tough conditions.

· Aerospace: Aircraft landing gear and engines use precision tapered bearings for reliability.

· Railways: Axle boxes in trains benefit from their high load capacity and long service life.

· Mining and Steel: Four-row bearings handle extreme loads in crushers and rolling mills.

Insight: The global bearing market is projected to reach $199.2 billion by 2026, with tapered roller bearings driving demand in automotive and heavy industry. We ensure our China tapered roller bearings meet these needs with top-tier quality.

We often get asked how tapered roller bearings stack up against other types, like straight (cylindrical) roller bearings or needle bearings. Here’s our breakdown:

Tapered: Handle both radial and axial loads due to their conical design. We use them in applications like car axles where thrust forces are present.

Cylindrical: Excel at radial loads but have limited axial capacity unless designed with ribs (e.g., NJ type). We choose them for pure radial load applications like electric motors.

Key Difference: Tapered bearings are better for combined loads, while cylindrical bearings prioritize radial load capacity.

Tapered: Larger conical rollers for heavy combined loads and moderate speeds.

Needle: Thin, long rollers for high radial loads in compact spaces, like automotive transmissions.

Key Difference: Needle bearings are compact but less suited for axial loads compared to tapered bearings.

Table: Tapered vs. Cylindrical vs. Needle Bearings

Feature | Tapered Roller Bearings | Cylindrical Roller Bearings | Needle Bearings |

Load Type | Radial + Axial | Radial (limited axial) | Radial |

Contact | Line (conical) | Line (straight) | Line (thin rollers) |

Speed | Moderate | Moderate to high | High |

Space | Moderate | Moderate | Compact |

Common Uses | Wheel hubs, gearboxes | Electric motors, pumps | Transmissions, small spaces |

Insight: We’ve found that proper alignment is critical for tapered roller bearings due to their conical design. Misalignment can shorten their lifespan, so we recommend precision installation techniques.

Why do we rely on tapered roller bearings for so many applications? Here’s what makes them stand out:

· Combined Load Capacity: They handle radial and axial loads, making them versatile for complex systems.

· Durability: Made from high-strength steel, they resist wear and shock loads with proper maintenance.

· Separable Design: The cone and cup are easy to install and replace, saving time during maintenance.

· High Precision: Matched pairs and double-row designs offer precision for applications like machine tools.

· Long Service Life: With proper lubrication, they last for years in demanding conditions.

Insight: We’ve seen that regular lubrication, such as using high-quality grease or oil, can double the service life of tapered roller bearings in high-load applications.

Here are some key takeaways we’ve gathered:

· Load Balance is Key: We match the taper angle to the application’s radial-to-axial load ratio to optimize performance.

· Quality Matters: Our China tapered roller bearings are crafted to meet global standards, ensuring reliability in critical applications.

· Future Trends: We’re excited about advances like ceramic hybrid tapered bearings, which offer lower friction and higher speeds for aerospace and high-tech industries.

What is a tapered roller bearing?

It’s a bearing with conical rollers that handles both radial and axial loads, used in applications like automotive wheels and industrial machinery.

What is the difference between tapered and straight roller bearings?

Tapered roller bearings handle both radial and axial loads due to their conical design, while straight (cylindrical) roller bearings primarily handle radial loads and need specific designs for axial loads.

What is the difference between needle bearings and tapered roller bearings?

Needle bearings have thin, long rollers for high radial loads in compact spaces, while tapered roller bearings use larger conical rollers for combined radial and axial loads.

What are the applications of tapered roller bearings?

They’re used in automotive wheels, gearboxes, construction equipment, aerospace, railways, and mining for their ability to handle combined loads.

Why are China tapered roller bearings popular?

Our China tapered roller bearings at WKB-Bearing offer high quality, cost-effectiveness, and durability, meeting global standards for heavy-duty applications.

What are the advantages of tapered roller bearings?

They provide combined load capacity, durability, separable design, precision, and long service life with proper maintenance.

How do I choose the right tapered roller bearing?

We recommend considering load type, speed, dimensions, material, lubrication, and environmental conditions, and consulting the manufacturer's data.

· BMC Bearing. (2020). Tapered Roller Bearings: What You Need to Know.

· SKF. (n.d.). Tapered Roller Bearings.

· NSK Americas. (n.d.). Tapered Roller Bearings Overview.

· Timken. (2020). Tapered Roller Bearings Catalog.

· Machine Design. (2015). Understanding Roller Bearings.

· GlobalSpec. (n.d.). Tapered Roller Bearings - Types and Applications.

· Bearing News. (2021). Tapered Roller Bearings in Industrial Applications.

· Emerson Bearing. (2018). Guide to Tapered Roller Bearings.

· ScienceDirect. (n.d.). Tapered Roller Bearings - Design and Performance.